Company Profile

Blog

-

From material selection to maintenance: A complete guide to using polyester hotel tablecloths

1. Why choose polyester as hotel tablecloths? Excellent durability High strength and wear resistance The breaking strength of polyester fiber is 2-3 times tha...

READ MORE -

Say goodbye to traditional filling! How does a microfiber pillow insert improve sleep quality?

In a fast-paced life, high-quality sleep has become the goal pursued by many people. As one of the key factors in sleep quality, the material and design of the ...

READ MORE -

5 major advantages of polyester plain napkins: durable, wrinkle-resistant, and easy to care for!

In the selection of tableware, the material of the napkin directly affects the user experience and the convenience of daily maintenance. Polyester (polyester fi...

READ MORE -

Hotel Polyester Flannel Blanket: Why is it a plus point for hotel accommodation?

1. Core advantages of polyester flannel blankets for hotels Polyester flannel blankets are far superior to other materials in hotel applications, and perfectly ...

READ MORE

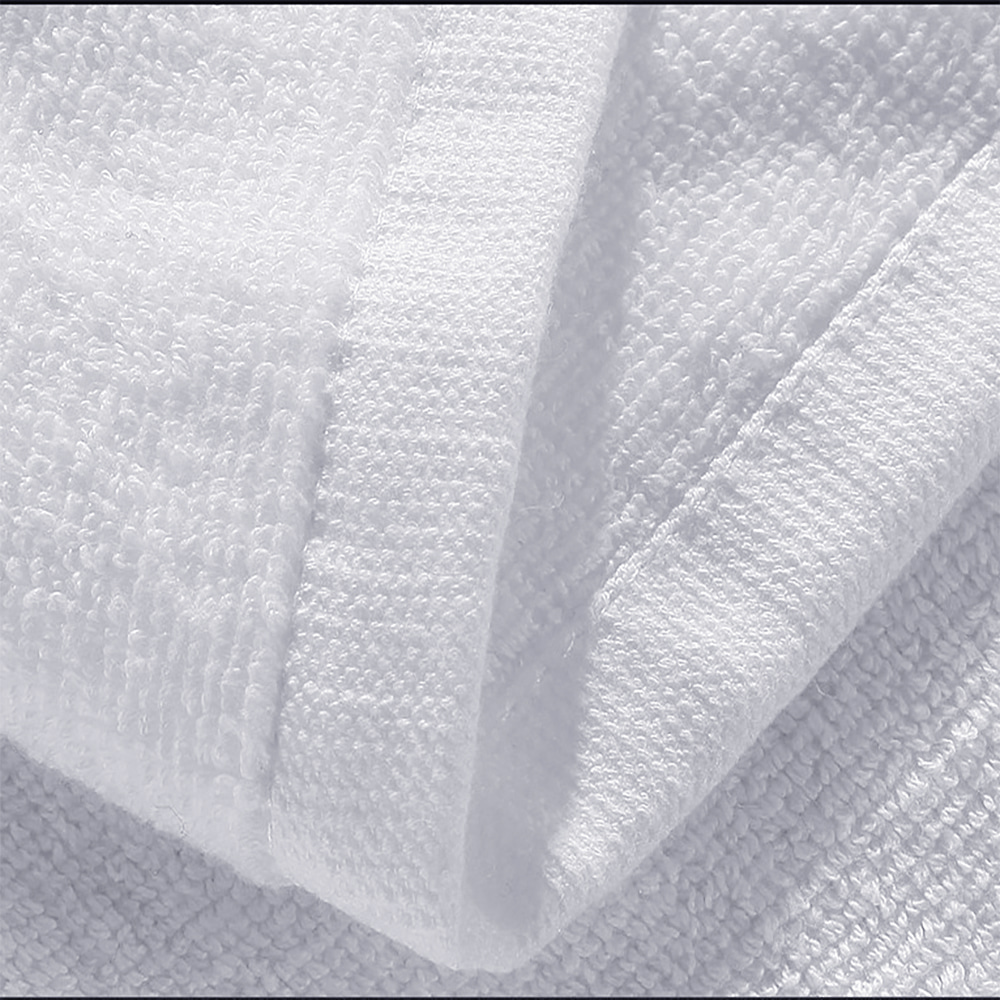

Embroidery Pure Cotton Bath Towel Industry knowledge

What is the specific process of CANWIN embroidered bath towel embroidery process?

Specific process of embroidered bath towel embroidery process

I. Preliminary preparation

1. Design and sample selection

The embroidery design of embroidered bath towels is the soul of the entire process. Designers transform creativity into exquisite pattern designs based on market demand, popular trends, and brand characteristics. After the design is completed, sample selection is required, that is, the thread color, base material, and embroidery process type of embroidery are determined to ensure that the final product is both beautiful and practical.

2. Pattern processing and plate making

The designed pattern needs to be processed by professional software and converted into a format that can be recognized by the embroidery machine, and then plate making is carried out, that is, using special software or mechanical tools to convert the lines, colors and other information on the pattern into needle instructions on the embroidery machine. This step requires extremely high precision to ensure that the embroidered pattern is consistent with the design draft.

Embroidery process

1. Embroidery frame and positioning

Put the prepared bath towel base fabric flat on the embroidery frame of the embroidery machine, and accurately position it through the positioning device on the machine to ensure the accurate embroidery position.

2. Embroidery machine operation

Start the embroidery machine, and according to the pre-set stitch instructions, the needle on the embroidery machine begins to embroider according to the outline of the pattern. During the embroidery process, the machine will automatically change colors and threads according to the complexity of the pattern and color changes, and adjust the stitch length and embroidery speed to achieve the best embroidery effect.

3. Quality control

During the embroidery process, a dedicated person is required to be responsible for quality control. CANWIN regularly checks the stitch density, color uniformity, pattern integrity, etc. of the embroidery to ensure that each bath towel meets the quality requirements.

Post-processing

1. Cleaning and trimming

After the embroidery is completed, the bath towel needs to be cleaned to remove the excess thread and debris generated during the embroidery process. At the same time, the embroidery edges are trimmed to make the pattern more neat and beautiful.

2. Ironing and shaping

Use professional ironing equipment to iron the bath towel to eliminate wrinkles and unevenness generated during the embroidery process. At the same time, ironing makes the embroidery part smoother and more closely fits the base fabric, improving the overall aesthetics.

3. Quality inspection and packaging

CANWIN will conduct strict quality inspection on the embroidered and post-processed bath towels, including checking whether the embroidery quality, color fastness, size specifications, etc. meet the standard requirements. Qualified products will be packaged, transported and sold.